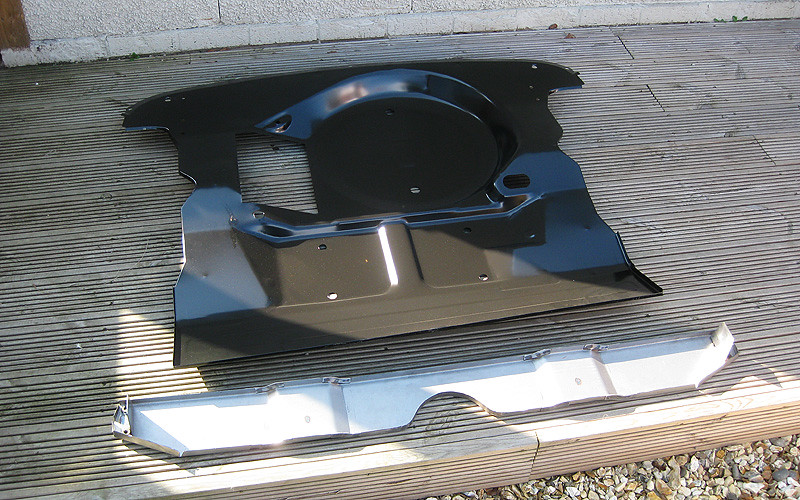

Fortunately, thanks to our very generous parents the wedding didn't entirely bankrupt me, so I got the project rolling again by ordering these bits from M-Machine.

Heritage boot floor skin and m-machine heelboard! For my first non-genuine panel, I was a bit apprehensive as to what the fit would be like, but it appears to be OK. Only minimal fettling to the floor to get a close dry fit.

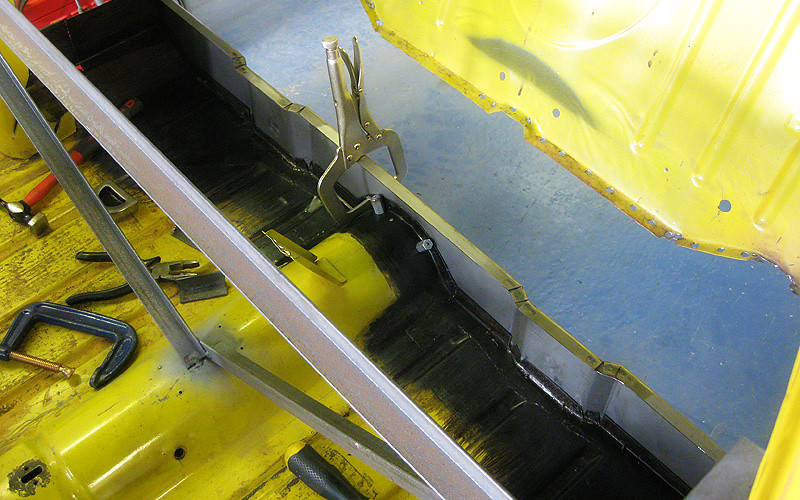

I whipped it off again to treat the enclosed surfaces with POR15. The mating surfaces on the old panel had suffered very badly from rust, so the more protection in this area the better, I think.

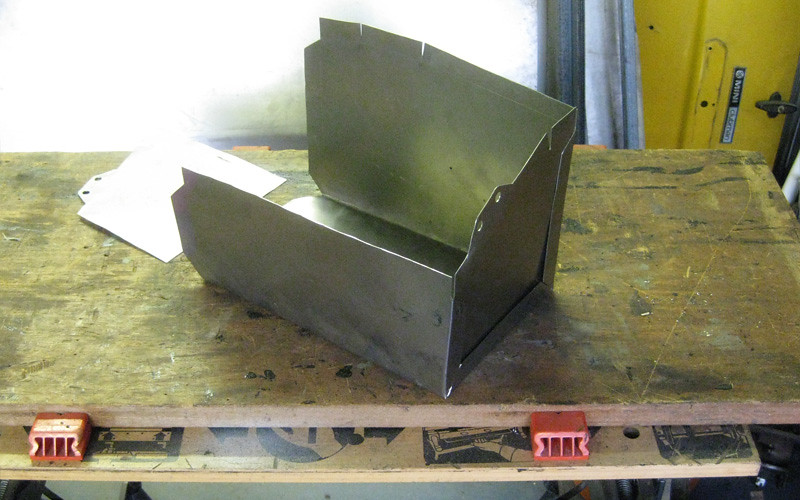

I ordered a boot floor without the battery box and fittings on purpose to save cash, so I set about making up a battery box using measurements from the old (unusable) one. Here is the cardboard model inserted into the new panel to check the dimensions.

When I was happy, I cut the pieces out of steel...

I started folding the metal to form the box, but by this point I was feeling the burn of the first full day of work in the garage for 2 months and decided to go and have a sit down instead!

Next step after this is to get the new heelboard welded in. Then I need to rebuild the lower part of the rear bulkhead where I have drilled it almost to pieces. I should then have 3 solid surfaces (including the newly repaired rear panel) on which to fit the boot floor. Not sure yet whether the wheel arches will be removed before or after the boot floor goes in.

As ever, if anyone spots any glaring errors or disasters about to happen, I'm all ears! :) Feels good to be making progress again!

No comments:

Post a Comment