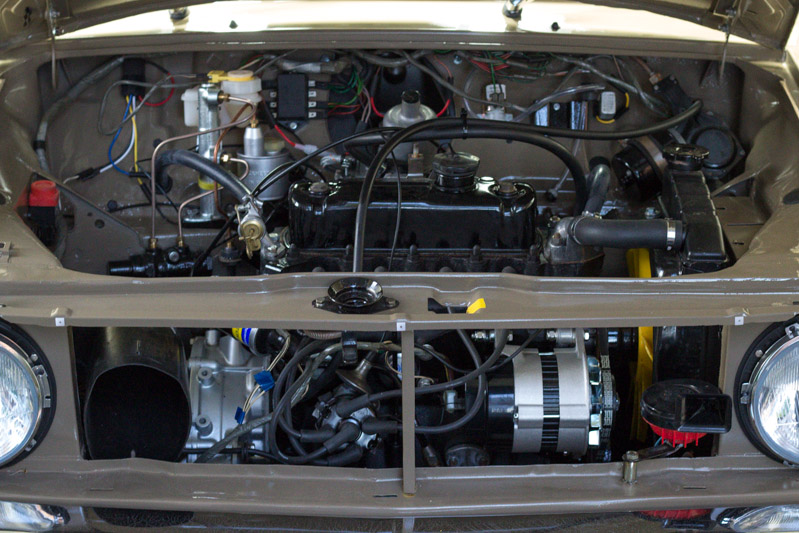

Spent the past few weeks ticking off all of the jobs the MOT threw up:

Speedo cable replaced (nice awkward job needed to be done from under the car!)

Brake fluid leak fix by replacing old copper washers.

Instrument bulbs replaced.

All grease nipples thoroughly pumped with grease.

Oil leak *touch wood* seems to be gone after tightening some things up down the front of the block.

Firewall thoroughly grommeted up.

Also relocated fuel reg/filter and put washer bottle back in correct place.

Also had assembled one rear brake a bit wrong which became very obvious, loud and hot when out driving. Fixed that too.

Now for some photos out and about. With all that done, I'm spending every free minute I get driving the car. Its awesome!

The only big issue I've got now is a rubbing noise coming from the back end when cornering sharply and sometimes under braking. I think its both sides, but definitely worse when turning right. Have checked brakes - seem fine, and had one hub to pieces - also seemed fine. My best guess is tires catching dampers as there is not loads of clearance. Does that sound likely? I'm going to test it next time out by marking the damper and seeing if it rubs off.

In other news, really pleased to have picked up a bargain 3 clock instrument set (albeit the 90mph version) and it is pretty worse for wear. Hopefully I can clean it up and bring it back to life because I'd really like to have a tacho in the car.