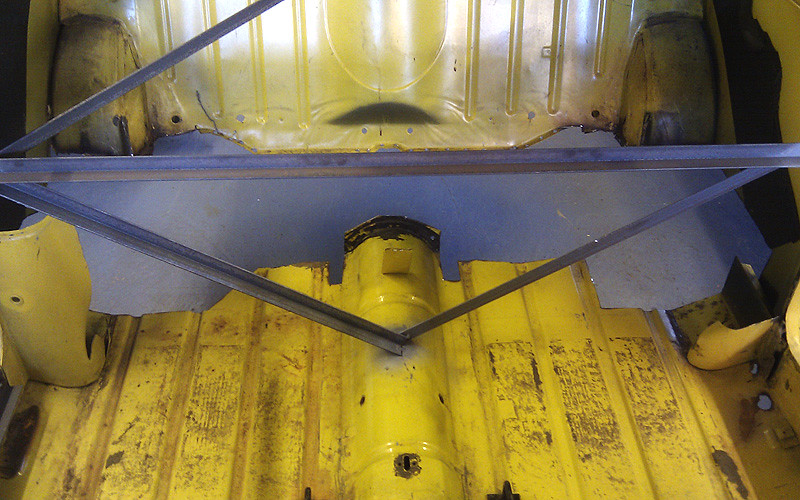

After much head scratching over best approach, I decided to keep as much floor as possible until I can get the car upside-down. I therefore resolved to get rid of all the rotten bits in this area (almost everything) and rebuild from the sound part of the floor outwards. First of all, I butchered the companion bins as they were rusty and patched anyway, and too difficult to remove cleanly.

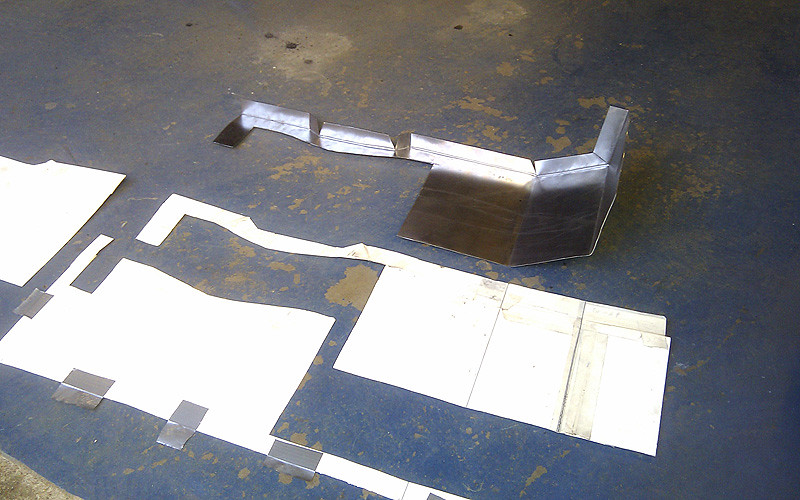

Then, with access to the whole floor, I made a couple of card templates to record the shape of the floor in its intact state.

I marked out the areas of rusty floor to be removed, and cut the whole end of the floor off in one piece including the heel board.

Bosh.

I know this looks drastic, but the whole discarded portion is cheese, and the various parts would have had to come out sooner or later. I'm not worried about losing rigidity as the joins to the quarter panels were non-existent anyway, and the temporary bracing I put in is doing a good job.

I could now tape in the templates I made earlier and trace the shape of the cut, and make up an accurately fitting floor repair:

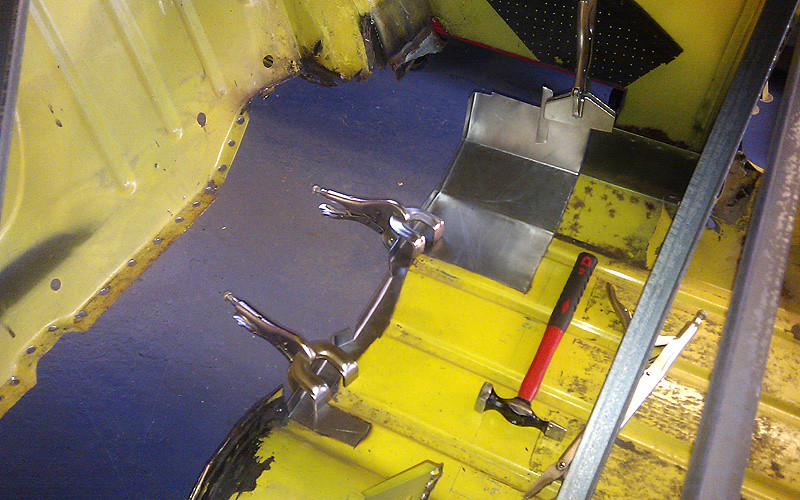

Here is the N/S repair roughly clamped in as a test. Annoyingly, I forgot to account for the one flute that intersects the join, but I will make sure that is welded up neatly at the final fitting. The inner sills will be replaced up to this repair so I won't fully seam weld that part in. I'm not going to have the holes in the new floor that were there previously (presumably for drainage?) as they seem to have been the first areas to rust.

Next job is to form the repair for the other side. I've got a piece of old heel board stuck to the tunnel still to remove, and then I should be able to weld this lot in and eventually get a new heel board fitted.

No comments:

Post a Comment