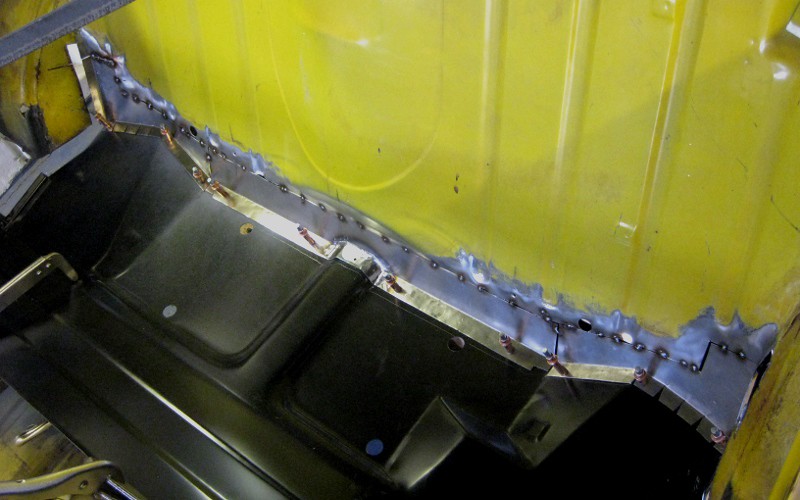

Lower bulkhead welded in and ground down. If my neighbours didn't hate me before, they probably do now! It took a fair while, but I wanted to get it looking reasonable as I'm probably not going to have a back seat, so this will be on show. Also got the new boot floor fully prepped to go in. Here it is with all plug holes drilled, paint stripped where required, and a double coat of POR15 on the joins, ready for welding in. While I was at it, I paint stripped both sides of the rear bulkhead.

Plug holes on rear panel drilled and all clamped up. Boot lid on to ensure fit.

Get yer weld on! I've got no idea why the heritage boot floor has a recess in the seat squab to fit the heelboard on the N/S but not the O/S. grr...

I finally bit the bullet and invested in a long-jaw clamp which was a big help as I could clamp right around the seat to the heelboard.

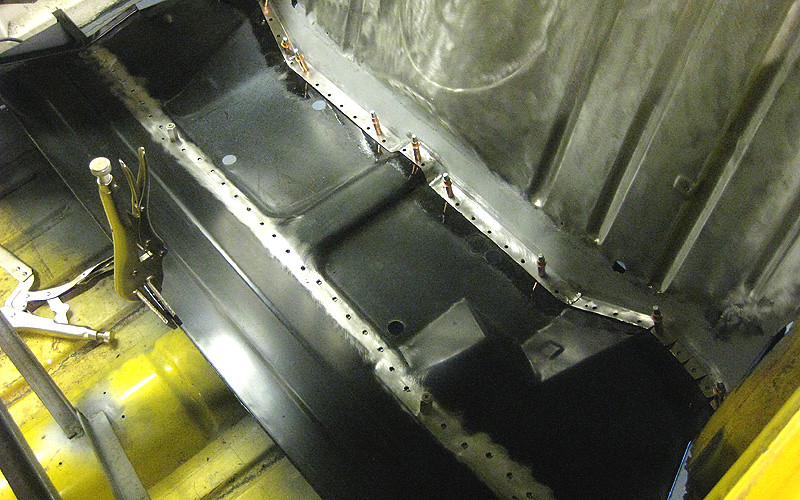

And the view from behind...

It looks like the remains of the old arches line up with the floor OK. Hopefully when I replace them (next job) it will all fit nicely. Time permitting, I should get today's welds ground down, cleaned up and primed tomorrow. Only a moron would leave that much bare metal exposed for very long at this time of year! -___-

No comments:

Post a Comment